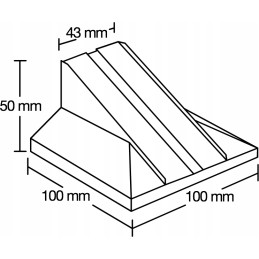

Adjustable terrace bracket 50-85 - basic propertiesAdjustment range for a joist with a maximum width of 100 mm - from 50 to 85 mm,

Load capacity of one support point - 400 kg,

Temperature resistance - from -30 to +90 degrees C,

The spacing of adjustable brackets should be adjusted to the recommendations of the manufacturer of the joists and boards for which the bracket will be a support - on average every 45 cm

Material from which the terrace brackets are made - polyethylene with refiners,

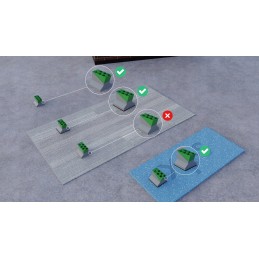

Installation method - we recommend a 'floating' construction without mounting to the ground, mounting to the joist with a screw 25 mm longer than the thickness of the joist, the screw should penetrate the common part of the wedge and the foot

It is worth paying attention to our bracket system, which allows for the adjustment of joists in the range of 10 mm to 294 mm. They are available in our other auctions.

Bracket assembly We start the assembly by spacing the brackets and placing the joists on them. Then, by appropriately moving the wedges on the feet, we level the joists.

The next step is to screw the joist to the bracket so that the screw goes through the wedge and foot connection. Drilling through the wedge and foot connection will block the possibility of changing the set height - even in the event of strong impacts on the floor or terrace surface.

Surfaces on which directly adjustable brackets can be mounted are hard surfaces such as:

concrete,

wood,

tiles,

stone, etc.

Additional system elements:

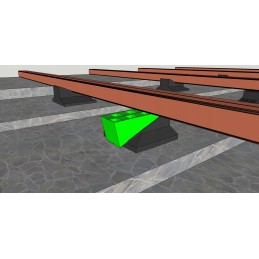

protective plate - used under soft surfaces such as roofing felt, styrodur, XPS board, etc. and closes the bracket from the bottom, thanks to which the weight is distributed over a much larger surface

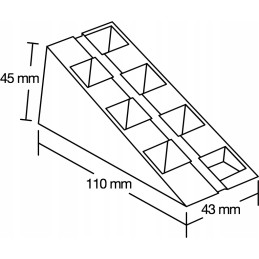

slope correctors 2.5% and 5% - used for inverted roofs and terraces with a greater slope

Both elements are available in separate auctions! Do you have any doubts about assembly? We will be happy to clarify any doubts!

Advantages of using the systemAdjustable terrace supports for joists are beneficial for many reasons, including:

Material quality - terrace supports are made of polyethylene from the first raw material, which ensures their high durability and resistance to cracking even when overloaded.

Precision of workmanship - the serration of the wedge and foot is very precisely made, which guarantees high load-bearing capacity and leveling with an accuracy of less than 1 mm.

Ease of leveling - using these supports allows for a quick and stable process of leveling the joists and allows you to achieve the appropriate height of the terrace surface, regardless of the level of the ground.

Available space - the supports provide sufficient space between the joists and the ground, which allows you to lay the joists and boards in any direction, without worrying about water retention.

Constant ventilation - thanks to the space between the boards, air can circulate freely, which ensures constant ventilation of the materials and avoids problems with mold.

Proven solution - Harpun adjustable terrace supports are a proven solution, with over 30 years of tradition in Denmark and Scandinavian countries.

Modular structure of the system - feet and wedges are compatible with other elements of the system, which allows for easy and quick assembly of the entire structure.

Adjustable Harpun terrace supports - choose an original solution!Regardless of whether it is a large terrace in the home garden or a terrace on the balcony, it is always a considerable expense. When building a terrace, you must be sure that it will last for years. The market is full of poor quality supports, often also made in China.

By choosing Harpun adjustable terrace supports, you can be sure that you are getting an original product manufactured in Denmark, which has been available on the market for over 30 years and tested by hundreds of installers, professionals, but also DIY enthusiasts who like to do everything themselves at home!